- Stock: In Stock

Project "Zig-Zag": From Idea to Implementation

The idea of creating an expedition knife with high adaptability to various conditions and tasks has been with me for a long time. I have had the opportunity to work with various tools in different conditions, such as machetes, kukris, axes, parangs, and survival knives. However, all of them undoubtedly had their limitations. I needed a tool that would be multifunctional, high-quality, lightweight, compact, and, of course, boldly attractive. And finally, after several years of research, tests, and experiments with prototypes, I created "Zig-Zag."

The "Zig-Zag" knife has high adaptability to various tasks due to its unique technological design features and the use of high-quality materials.

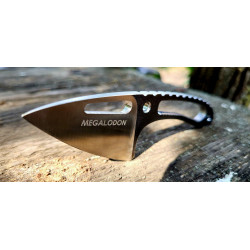

KNIFE STEEL:

The "Zig-Zag" knife is made of high-quality stainless steel of grade N690, produced by the Austrian corporation Bohler-Uddeholm. This steel is free from harmful impurities, resistant to active corrosion, and capable of withstanding high physical loads. It is widely used in the pharmaceutical and food industries. Drills, milling cutters, and bearings are made from this steel. It is also widely used in the production of long-bladed and tactical knives by well-known global companies.

THERMAL AND CRYOGENIC TREATMENT:

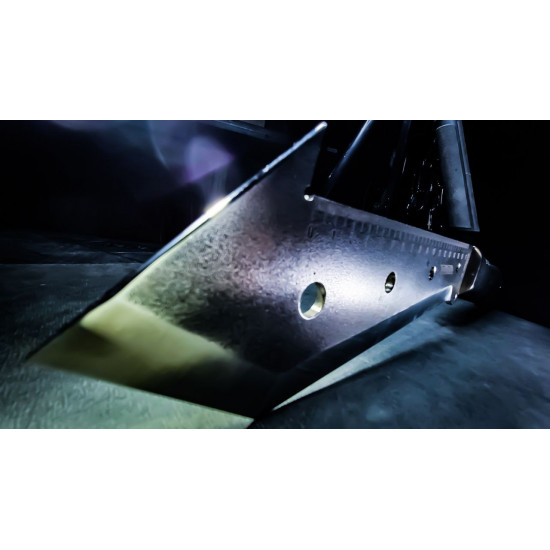

The "Zig-Zag" undergoes thermal and cryogenic treatment procedures in a special reservoir with liquid nitrogen. These stages of the process give the knife improved cutting characteristics and make its edge more aggressive. The material's hardness reaches a level of 58-59 HRC, providing high blade strength and maintaining sharpness for a longer time.

SHARPENING:

The "Zig-Zag" knife features a double-sided lens-shaped sharpening, manually crafted for each knife. The blade with this lens-shaped sharpening on the cutting edge acts similarly to a wedge, spreading the cut material while reducing friction and resistance. Knives with lens-shaped sharpening prove to be significantly more efficient in making deep cuts compared to factory knives with a V-shaped sharpening (assuming comparable blade thickness). This is due to the reduction of material "adhesion." The lens-shaped sharpening on the "Zig-Zag" knife can be conveniently maintained even in expedition conditions using simple tools.

Coating and Treatment:

The knife itself does not undergo chemical treatment. A slight blade grinding process takes place while preserving the original and relief pattern of the steel.

Specific areas of the knife undergo polishing to achieve a working shine. The edge of the smaller blade has a lens-shaped and polished finish, contributing to the formation of rounded indentations on the surface of materials, such as wooden handles of tools, when struck. This provides better grip on these tools. This is particularly useful when working with a hook, achieving a directed hole when piercing materials, such as metal.

The edge of the larger blade is equipped with rigid abrasive edges, intended for creating shavings from materials or using it as a striker for a fire starter. The edge of the larger blade also undergoes polishing.

MULTIPURPOSE HOOK:

The hook located at the beginning of the "Zig-Zag" knife is multifunctional. It allows pulling cut branches towards oneself, punching through metal and other materials, pulling wire, attaching ropes to other objects, and removing thin shavings from various surfaces. At the base of the hook, there is a hole that securely fixes the knife on materials such as wire, rope, or flat ribbons.

HANDLE:

The handle of the "Zig-Zag" knife is made of polyurethane by the method of integral casting, specially designed considering the technological aspects of this type of knife.

The handle material is a two-component polyurethane of German production with optimal hardness.

The main task of the handle is to provide maximum comfort during knife use with various grips: primary, reverse, vertical, grips for delicate work, and when using the knife with both hands.

During operation, the operator's hands do not come into contact with the knife tang, eliminating the possibility of electric shock, for example, when the blade touches live wires. In addition, the handle minimizes recoil during chopping strikes and ensures comfortable knife use even in freezing conditions without gloves.

Special recesses are present on the surface of the handle, placed selectively in areas of active contact,

the handle's design includes a bulbous stopper at the end, preventing the hand from slipping during chopping strikes and providing comfort when the blade is in a vertical position, for example, for penetrating the ground or other materials.

A small hole is provided at the end of the handle, where a lanyard or rope ring can be inserted for vertical suspension (not for carrying the knife!).

The handle is tightly connected to a titanium bolster, creating a unified monolithic structure.

The handle is connected using strong and easily removable elements: stainless steel bolt, washer, and nut, manufactured in Switzerland.

The polyurethane handle of the "Zig-Zag" knife maintains its characteristics over a wide temperature range from -60 to +120 degrees Celsius. Furthermore, it withstands significant impact loads and is the most durable and wear-resistant among all flexible materials created by humans.

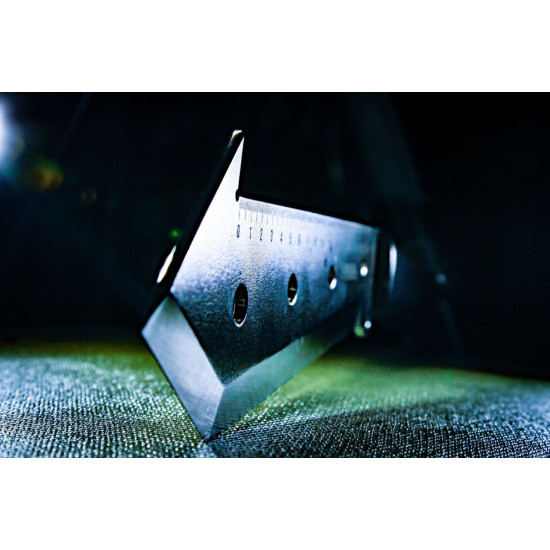

HOLES:

Four holes of various diameters, located along the entire length of the blade, reduce its weight and affect the knife's balance, positively impacting convenience during work. These holes can be used in conjunction with a rope for various tasks. For example, a loop of rope can be inserted into the largest hole to hold the knife in a vertical position, allowing its use for ground manipulation, such as pulling or cutting.

The operator firmly holds the knife by the loop with one hand, while the other hand is on the handle. The knife is driven into the ground with one hand, after which the second hand pulls on the loop. This method allows for intensive extraction of soil towards oneself.

Additionally, the knife can be used as a primitive peg by tying a rope to it through one of the holes for secure anchoring in various types of soil or materials.

Additional holes corresponding to the holes in the blade can be made in the sheath. Assuming the knife is in the sheath, the rope can be threaded through the second hole from the bolster and securely fastened with a knot on the reverse side.

With this connection of the rope to the central part of the knife, it can be thrown, for example, onto tree branches to provide grip and form a fixation point.

The four main holes also increase the strength of the blade construction under serious lateral and longitudinal loads, representing so-called reinforcement points.

The fifth hole is located on a semicircular protrusion in the bolster area and is intended for securing a safety loop. This ensures safety during active knife use. The loop should be securely fastened to the operator's hand, preventing the knife from accidentally slipping out of the hand.

DIMENSIONS AND WEIGHT:

The dimensions and weight of the knife were carefully calculated based on numerous tests in restricted spatial conditions, including various types of work with different materials.

The weight of the "Zig-Zag" knife is 560 grams excluding the sheath. The blade thickness is 4 mm. The main blade has a length of 17 cm, and the secondary blade is 6 cm. The width of the bevels on both blades is 2 cm, and the hook is 2 cm. The widest part of the blade has a width of 9 cm. The knife handle has a length of 14 cm. The overall length of the knife is 38 cm.

BASIC CONFIGURATION:

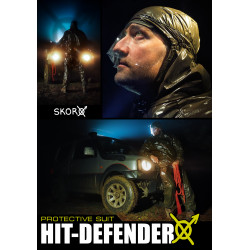

The kit includes the "Zig-Zag" knife with a black handle and sheath made of black Kydex, as well as a safety loop and a universal cover for storing the knife or equipment. The cover has the option to be attached to the MOLLE system and with compression straps.

ADDITIONAL OPTIONS:

In the standard configuration, the "Zig-Zag" knife comes with a black handle and sheath made of black Kydex. If desired and for an additional fee, you can order sheaths in a different color (coyote brown, olive, multi-cam). It is necessary to clarify the availability of knives with handles in olive or coyote brown colors when placing an order. It is also possible to order a cover in a different color and design for an additional fee. Any engraving can be ordered in addition to the one already on the item.

ENGRAVING:

The knife is equipped with laser engraving on one side, presented in centimeters from 0 to 18 centimeters, and on the other side, in inches, from 0 to 7 inches. This provides convenience when measuring objects, working with maps, etc. It also aids in calculating the distance to objects at a distance.

SHEATH:

To ensure safe storage and transportation of the "Zig-Zag" knife, sheaths made of American Kydex are used, equipped with thirteen stainless steel eyelets around the perimeter and a reliable lock construction. An anatomical lock allows for quick removal of the knife from the sheath. If necessary, the lock can be installed on the reverse side of the sheath. The sheaths are individually crafted for each knife.

KNIFE COVER:

The "Zig-Zag" knife comes with a convenient cover for storage and transportation. The cover is made of black cordura. It can be attached to gear using the MOLLE system. The cover is equipped with a loop for carrying by hand or on the belt, as well as three compression straps. It can be used to carry essential gear, a plastic one-and-a-half-liter water bottle, or as a compression cover for clothing. The hardware of the cover is made of high-quality material - acetal from South Korean production.

MANUFACTURING DATE:

Each "Zig-Zag" has an individual manufacturing date, including the day, month, and year. These numbers can serve as a unique registration number for the knife.

COMPLIANCE WITH REGULATIONS:

The Zig-Zag knife has successfully passed examination and confirmed that it is not considered a cold weapon within the territory of Ukraine, making it legal equipment for use.

| General | |

| Material | Stainless steel grade N690 Kydex scabbard |

| Dimensions | 135*4 mm |

| Weight | 0.56 kg |

-250x250h.jpg)

-250x350h.jpg)